TW-R2

Real Videos

| Classification of Dies | Number of Cavities | Production Rates per Hour/3.2r.p.m. |

Classification of Dies | Number of Cavities | Production Rates per Hour/3.2r.p.m. |

|---|---|---|---|---|---|

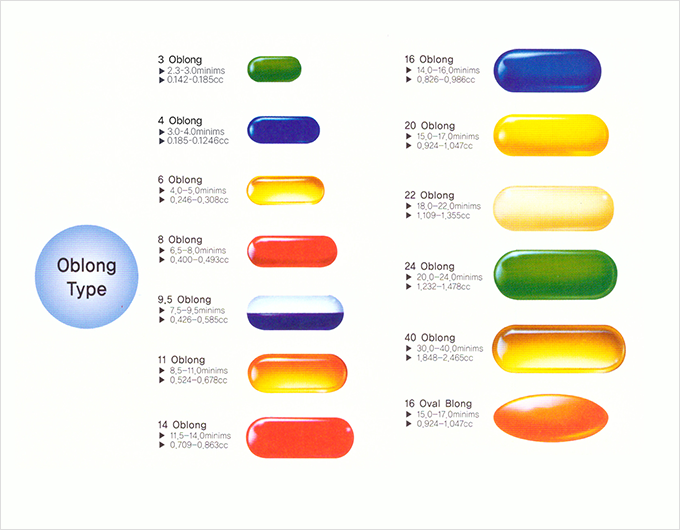

| Oval #2 | 936 | 179,712 | Oblong #16 | 231 | 44,352 |

| Oval #3 | 793 | 152,256 | Oblong #12 | 251 | 48,129 |

| Oval #4 | 588 | 112,896 | Oblong #10 | 300 | 57,600 |

| Oval #5 | 561 | 107,712 | Oblong #9.5 | 333 | 59,328 |

| Oval #6 | 546 | 104,832 | Oblong #8 | 366 | 70,272 |

| Oval #7,5 | 408 | 78,336 | Oblong #6 | 405 | 77,760 |

| Oval #10 | 384 | 73,728 | Oblong #5 | 444 | 85,248 |

| Oval #12 | 341 | 65,472 | Oblong #4 | 535 | 102,720 |

| Oval #20 | 264 | 50,688 | Oblong #3 | 648 | 124,416 |

| Oval #30 | 237 | 45,504 | Round #90 | 120 | 23,040 |

| Oval #40 | 183 | 35,136 | Round #80 | 126 | 24,192 |

| Round #28 | 168 | 32,256 | |||

| Oblong #22 | 231 | 44,352 | Round #5 | 621 | 119,232 |

| Oblong #20 | 231 | 44,352 | Round #2 | 836 | 160,512 |

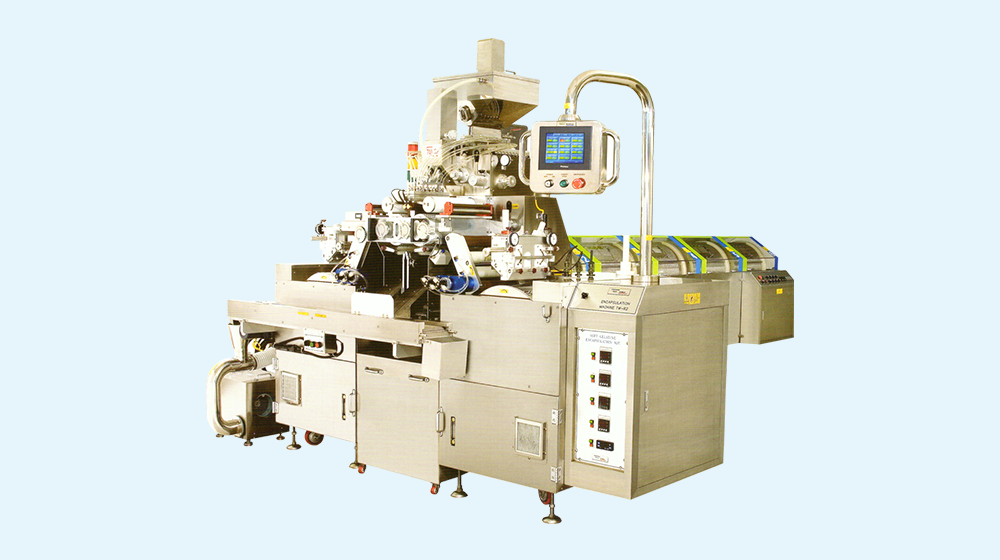

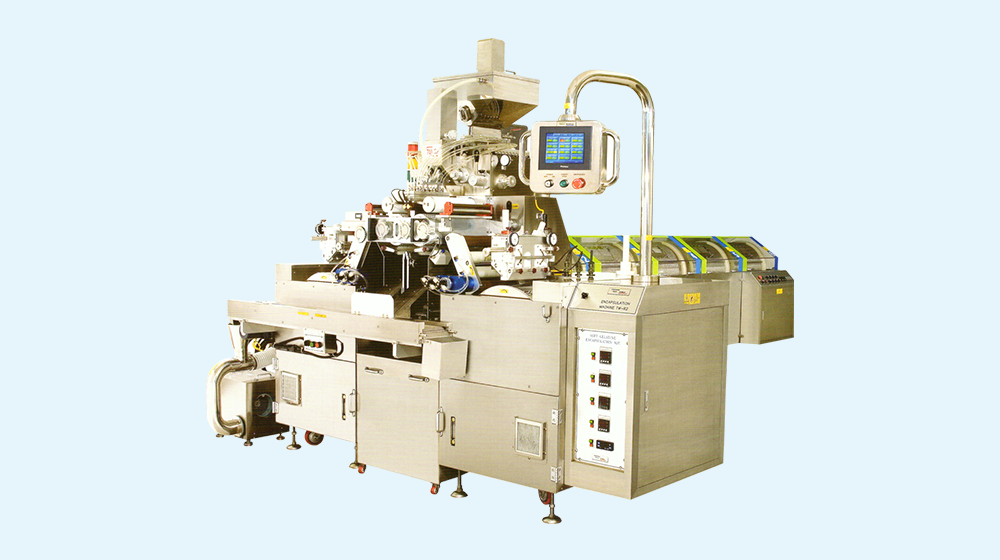

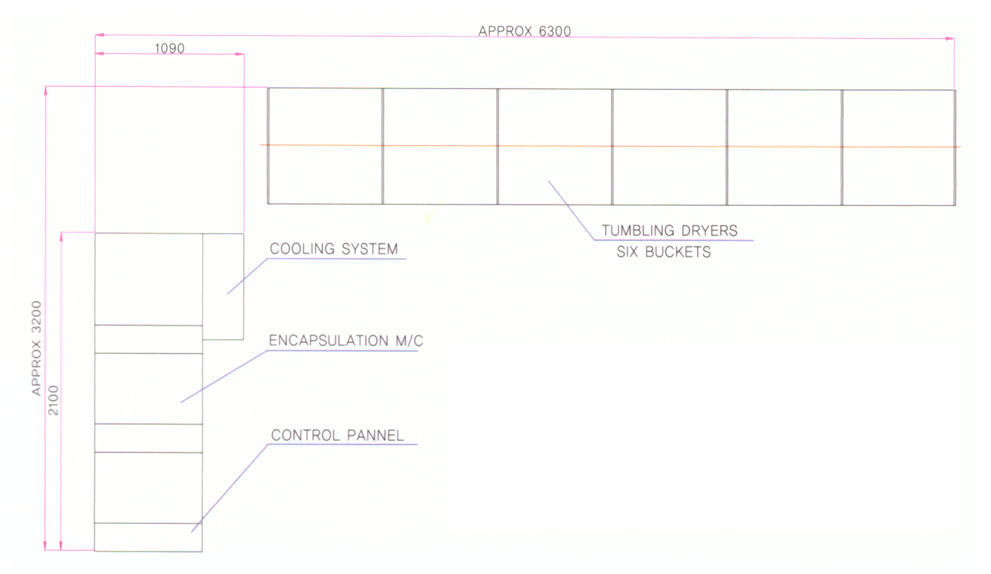

Technical Data

- Dimension

- D1,090 X H2,150 X W2,450

- Weight

- 1,900KG

- Power

- 19,5KW

- VoItage

- 220V,380V,415V,440V

- Dimension

- D820 X H1,130 X W5,030

- Weight

- 1,500KG

- Power

- 7KW

- VoItage

- 220V,380V.415V,440V

This patented die roll pressurizer is equipped with a magnifying glass and lamp in the front side and it is helpful for you to accurately set the zero point of die rolls.

- Also, it is also possible to check the pressure by using a digital reading during installation of die rolls, so any operators can install it easily.

- Most of all, the die roll pressurizer extends rapidly the use period of die roll from 10,000 hours to 20,000 hours.

- Additionally, it efficiently ensures trouble-free production of high quality of capsules because there occurs no pressure change even in extended operation.

It can accurately control thickness of a gelatin film and feed gelatin stably and effectively by using a temperature sensor. Its interior and exterior are made of SUS 316 and aluminum material respectively. So it is hygienic and light weight and can be installed and maintained by any operators in an easy and safe manner. In thermal conductivity and preservation, it has 2,8 times higher than that of other competitor's products made of brass.

The die roll push bar is developed and designed in a digital type to make the input data of the forming die roll zero during the production of the capsule. Since the thickness of gelatine and the pressure required for the forming roller are accurately controlled by the digital system, the life span of the forming roller is extended. And it is possible to produce an excellent quality of capsules in an equal thickness by keeping the pre- and post-pressure of the forming roller.

Heat sensors are installed in the left and right cooling drum to optimize the

production of the high quality of gelatin. And the automatic controller is installed to keep temperature at a constant level up to +/-0.10.

Since no pressure is generated in the drum, it ensures safe operation. The cooling drum precisely turns with the concentricity 0.05 to produce a high quality of gelatin.