Summary

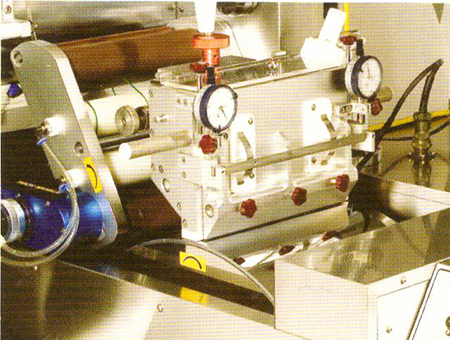

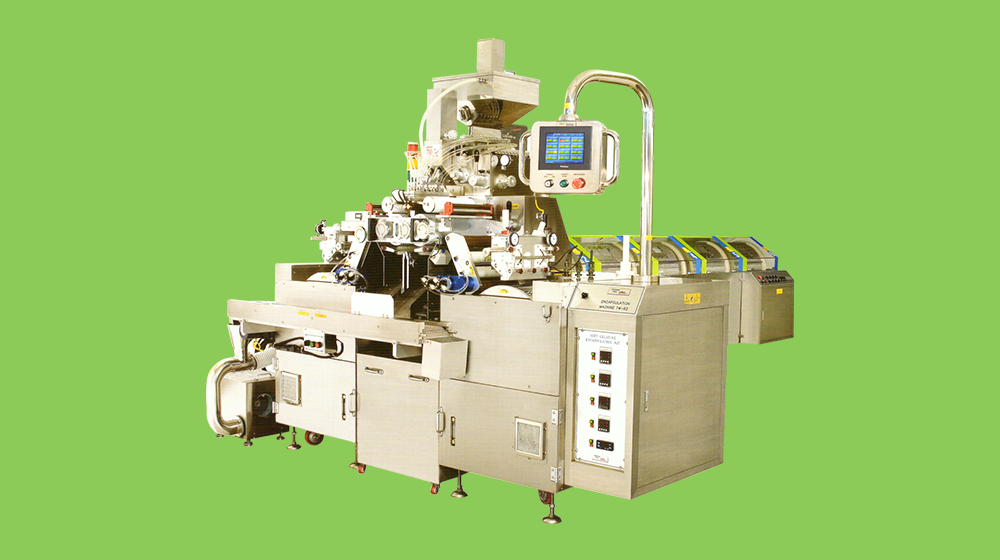

It is the high speed soft gelatin capsule machine supporting avg. 6~ max. 10rpm which developed for the first time in the world and

it is the equipment offering the best solution among the soft gelatin capsule filling machines producing soft capsule.

-

Performance and safety of TW-R2 S was verified by Korea Evaluation of Industrial Technology (KEIT) and received CE certificate in 2009. Also we have 2 patents and 3 utility models related to this product.

-

Key advantages

-

First, It is the equipment suitable for the standard of sanitation and safety of food and medicine so we are using verified materials such as SUS 316, Al, Teflon coating and silicon which are not harmful to human body.

-

Second, it has excellent durability. Our equipment has no minor problem and even in a long operation, it keeps precision and operates normally.

-

Third, we raised the efficiency of maintenance through use of standard part and standard.

-

Fourth, it is convenience of operation. (one touch structure, touch screen panel, hub system and so forth)

-

Lastly, we are sure that the high speed soft gelatin capsule filling machine (TW-R2 S) maximized product completion through past 10 years of manufacturing and exporting experience is the best solution which can bring much more profits to you.